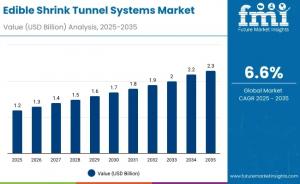

Edible Shrink Tunnel Systems Market to Witness 6.6% CAGR by 2035 - APAC, Europe, and USA Accelerate Demand for Packaging

Japan’s edible shrink tunnel systems market, valued at USD 200.0 mn in 2025, is led by steam shrink tunnel systems favoured for uniform heat distribution.

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The Edible Shrink Tunnel Systems Market is on a robust upward trajectory, expected to grow from USD 1.2 billion in 2025 to USD 2.3 billion by 2035, reflecting a strong compound annual growth rate (CAGR) of 6.6%. This growth is primarily driven by increasing demand for eco-friendly and edible packaging solutions across the food, bakery, confectionery, and pharmaceutical industries. As global manufacturing pivots toward sustainability, edible shrink tunnel systems are emerging as an integral part of packaging automation and waste reduction strategies.

According to recent data, electric heating systems dominate the market with a 41.2% share in 2025, followed by steam-based tunnels, which are preferred for uniform heat distribution and reliable sealing. The Asia-Pacific region, led by South Korea (7.0% CAGR), is forecasted to be the fastest-growing market, while North America and Europe continue to adopt smart and sustainable packaging automation technologies.

Unlock Growth Potential – Request Your Sample Now and Explore Market Opportunities!

https://www.futuremarketinsights.com/reports/sample/rep-gb-27064

Market Dynamics: Growth Drivers and Technological Evolution

Rising consumer demand for biodegradable and edible packaging is accelerating the deployment of shrink tunnel systems that seal food items using heat-responsive edible films. These films, often composed of proteins, polysaccharides, and biopolymer composites, serve as safe and functional coatings that reduce packaging waste while extending shelf life.

Manufacturers are increasingly adopting electric and steam heating technologies due to their high energy efficiency, zero-emission operation, and compliance with global sustainability standards. Between 2025 and 2030, the market is expected to add USD 0.4 billion in value as automation expands in bakery and snack packaging. From 2030 to 2035, innovations in edible film compatibility, heat control precision, and hybrid tunnel designs are projected to add an additional USD 0.7 billion.

Segmental Insights: A Breakdown of Key Market Drivers

1. By Machine Type – Steam Systems Lead the Way

Steam shrink tunnels are projected to hold a 38.7% share in 2025, driven by their superior sealing efficiency and adaptability across edible films. These systems ensure uniform shrink quality while minimizing product deformation—an essential feature for delicate bakery and confectionery items. By 2035, steam systems are expected to integrate digital temperature control and hybrid power technologies for both industrial and small-scale food production lines.

2. By Heating Technology – Electric Heating Dominates

Electric heating will maintain a 41.2% market share in 2025 due to its precision, safety, and energy-saving attributes. Continuous R&D in smart sensors and renewable power integration is making electric heating systems the preferred choice in regions enforcing strict environmental compliance.

3. By Material Compatibility – Protein-Based Films Gain Ground

Protein-based edible films are projected to capture a 36.5% market share by 2025, favored for their flexibility and superior shrink performance in bakery and confectionery applications. Emerging biodegradable blends and allergen-free edible coatings will further boost their adoption across pharmaceutical and food packaging lines.

4. By End-Use Industry – Food and Beverages Remain Dominant

The food and beverage sector will account for 43.4% of the total market in 2025, reflecting strong adoption in bakery, dairy, and ready-meal packaging. With increasing hygiene standards and automation integration, the sector will continue to be a key driver of edible shrink tunnel installations through 2035.

Regional Outlook: Growth Perspectives by Key Markets

United States (CAGR: 6.5%)

The U.S. market is witnessing a steady rise in smart automation and eco-friendly packaging adoption. With the bakery and dairy sectors at the forefront, companies are upgrading to advanced shrink systems that enhance food safety and efficiency while complying with FDA packaging standards.

• High adoption in bakery and dairy sectors

• FDA standards reinforcing sustainable system design

• Automation driving production consistency

Germany (CAGR: 6.2%)

Germany’s leadership in packaging machinery exports underpins its strong market presence. The nation is accelerating R&D in edible shrink materials and sensor-based automation, supporting its transition to circular economy-driven packaging.

• R&D boosts edible shrink material innovation

• Biopolymer adoption increases across Europe

• Process automation enhances quality and consistency

United Kingdom (CAGR: 6.3%)

The UK is prioritizing biodegradable packaging for bakery and ready-meal sectors, supported by clean-label initiatives and government sustainability incentives. Rising automation in food processing lines is creating lucrative opportunities for local equipment manufacturers.

• Bakery automation strengthens adoption

• Clean-label movement boosts edible packaging demand

• Government incentives fuel R&D investment

China (CAGR: 6.4%)

China’s market is advancing rapidly due to modernized food manufacturing and a strong push for circular economy practices. Dairy and meat packaging lines are adopting energy-efficient, digitally controlled tunnels for edible shrink coatings.

• Government support for sustainable manufacturing

• Increased investment in edible film research

• Local manufacturers expanding export reach

India (CAGR: 6.3%)

India’s modernization of food and dairy packaging facilities is fueling demand for energy-efficient shrink tunnels. Government initiatives promoting eco-friendly packaging and export competitiveness further strengthen local manufacturing capabilities.

• Rapid growth in food processing infrastructure

• Increased use of hybrid tunnel designs

• Local firms expanding export potential

Japan (CAGR: 6.9%)

Japan’s market emphasizes compact, precision-engineered tunnel systems, ideal for space-constrained production lines. Continuous R&D in edible films for bakery and confectionery enhances product innovation.

• Compact, automated systems favored

• Innovation in edible film formulations

• Exports of small-scale equipment rise

South Korea (CAGR: 7.0%)

South Korea leads the region with rapid integration of smart control and hybrid heating in food, cosmetics, and confectionery packaging. Focus on smart energy management and sustainable materials cements its role as a regional innovator.

• Automation and IoT integration drive growth

• Energy-efficient designs enhance sustainability

• Expanding edible coating applications across industries

Purchase Full Report for In-Depth Insights

Gain complete access to detailed forecasts, market segmentation, competitive benchmarking, and trend evaluations — purchase the full report here:

Buy Full Report – https://www.futuremarketinsights.com/checkout/27064

Competitive Landscape and Industry Developments

The edible shrink tunnel systems market is moderately fragmented, featuring prominent players such as Texwrap (Robopac), Eastey, Shanklin (Sealed Air), PAC Machinery, ULMA Packaging, Smipack, Heat Seal, nVenia (Duravant), Harpak-ULMA, and Amar Packaging.

• Texwrap and Shanklin lead with global footprints and continuous technological innovation.

• nVenia (Duravant) emphasizes automation and hybrid heating integration.

• Amar Packaging and Smipack cater to compact, cost-efficient edible packaging systems across Asia.

Recent developments highlight accelerating innovation:

• April 2024: PAC Machinery launched the Clamco 6800CS-HS high-speed continuous side sealer, enabling higher throughput for varied food items.

• March 2025: ULMA Packaging expanded production capacity in Oñati, Spain, focusing on advanced automation systems to enhance global supply.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Have a Look at Related Research Reports on the Packaging Domain:

PET Stretch Blow Molding Machines Market - https://www.futuremarketinsights.com/reports/pet-stretch-blow-molding-machines-market

Rigid IBC Market - https://www.futuremarketinsights.com/reports/ribc-market

Food Tray Market - https://www.futuremarketinsights.com/reports/food-trays-market

FIBC Market - https://www.futuremarketinsights.com/reports/fibc-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.